Today, continuous improvement is not just a best practice — it’s a necessity.

But fostering a culture of continuous improvement isn’t about sending developers to a conference once a year or adding a “retrospective” to your sprint cycle. It’s about embedding a mindset, a set of behaviors, and systems that help teams get better — every single day.

In this article, we’ll explore how engineering leaders can intentionally build and scale a culture of continuous improvement that drives performance, innovation, and long-term team growth.

Why Continuous Improvement Matters in Engineering

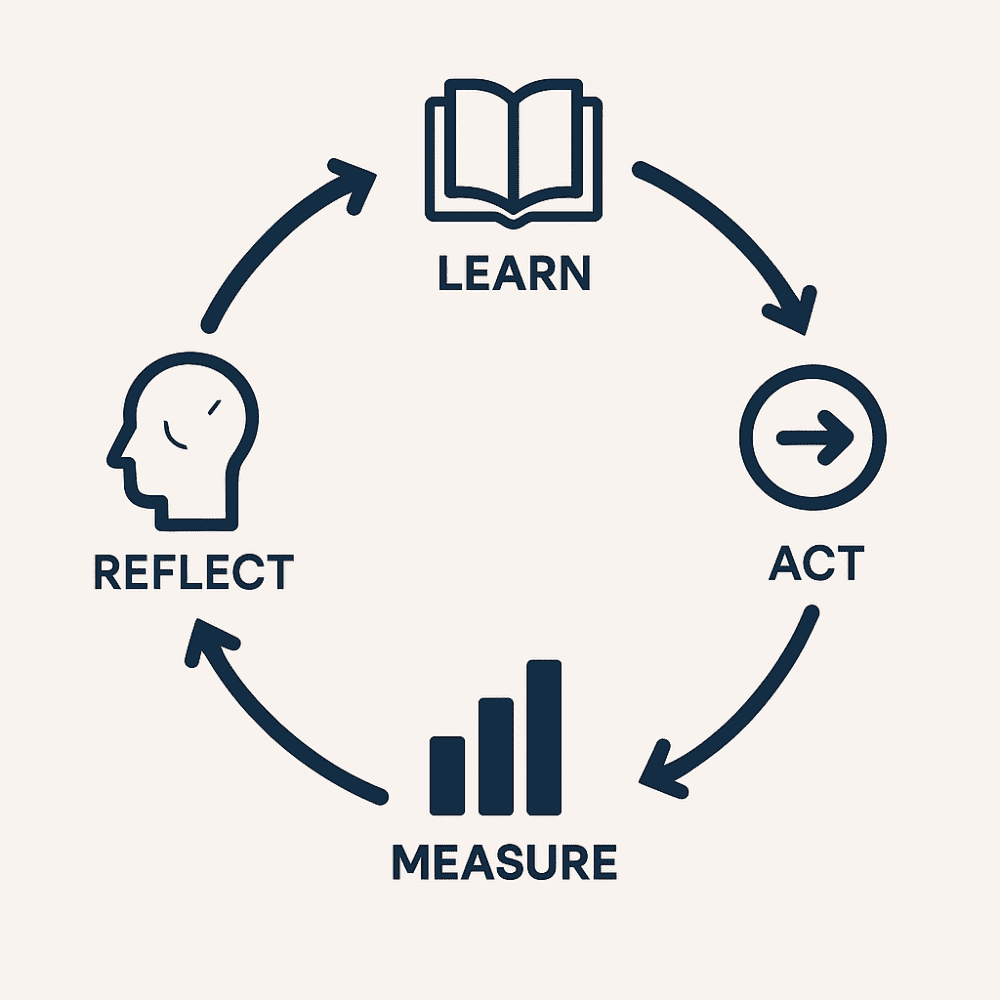

Learn -> Act -> Measure -> Reflect

The concept of continuous improvement (originating from Lean and Kaizen principles) means always looking for ways to make things better — whether it’s your code, your process, your tools, or your team dynamics.

In engineering, it pays off in powerful ways:

Higher code quality and system stability

Faster delivery cycles and reduced waste

Increased team engagement and learning

Better collaboration across disciplines

Greater adaptability in a changing market

But perhaps most importantly, continuous improvement makes engineering teams resilient. Teams that learn and adapt consistently outperform those that rely on talent alone.

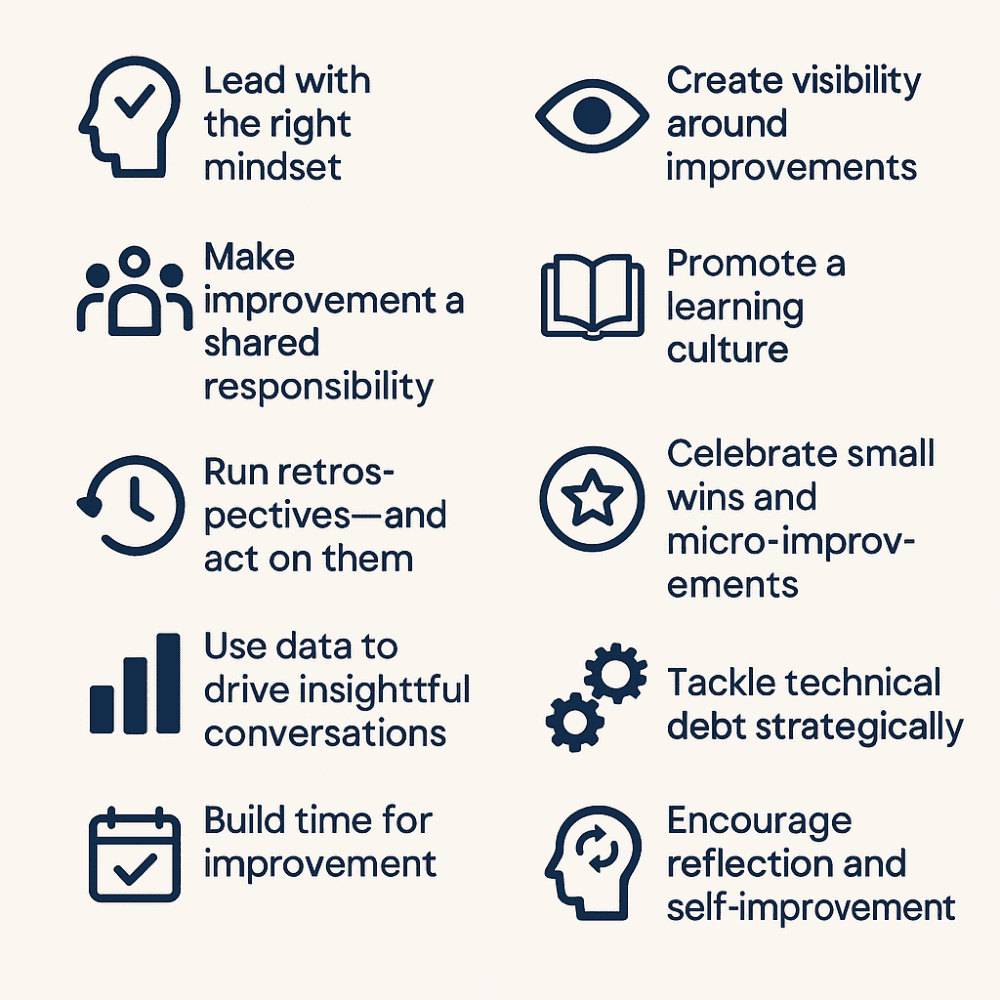

1. Lead with the Right Mindset

Culture begins at the top. If leaders don’t model continuous improvement, teams won’t embrace it either.

What leadership looks like in this context:

Admitting when something could be done better

Asking for feedback and acting on it

Valuing learning over blame

Celebrating iteration, not just outcomes

2. Make Improvement a Shared Responsibility

In many organizations, improvement is someone else’s job — the Scrum Master’s, the manager’s, or a “process excellence” team. That model doesn’t scale.

In high-performing engineering cultures, every individual feels empowered to suggest, drive, and test improvements.

Ways to enable this:

Create safe channels for ideas (internal Slack threads, retro boards, open office hours)

Empower engineers to own process changes, not just follow them

Reward improvements in workflows, documentation, tests, or team practices — not just features shipped

3. Run Real Retrospectives — and Act on Them

Too many teams run retros as a ritual and ignore the output. This breeds cynicism.

To create value:

Create psychological safety so people can speak freely

Focus on themes, not just isolated issues

Always assign action items with owners and follow-up in the next sprint

Regularly experiment with retro formats to keep them fresh and insightful

A well-run retrospective is one of the most powerful tools for continuous improvement — if you actually close the loop.

4. Use Data to Drive Insightful Conversations

Gut feeling matters — but data enables better decisions and helps teams pinpoint areas for improvement.

Track and discuss:

Lead time and cycle time for features

Code review wait times

Bug frequency or escaped defects

MTTR (mean time to recovery) on incidents

Technical debt metrics or test coverage

But don’t weaponize metrics. The goal is not to create pressure, but to spark curiosity and dialogue.

5. Build Time for Improvement Into Your Cadence

If improvement is always “next sprint,” it will never happen. Make it part of your core sprint rhythm.

Ideas to consider:

Allocate a fixed percentage of sprint capacity for improvements

Run dedicated “Engineering Excellence” sprints quarterly

Implement “Fix-It Fridays” for low-priority tech debt and tools

Allow engineers to nominate items during planning that improve long-term efficiency

This sends a message: improvement is work. It’s not an afterthought — it’s a critical part of delivering value.

6. Create Visibility Around Improvements

People replicate what they see. When improvements are visible, appreciated, and celebrated, they multiply.

Tactics:

Maintain a team improvement log or changelog in your Confluence/Notion

Create a Slack channel like #engineering-wins for sharing improvements

Present key wins during all-hands or town halls

Shout out individuals or teams for proposing, testing, or scaling better ways of working

When engineers see their contributions to improvement are valued, it fuels a virtuous cycle.

7. Promote a Learning Culture

Continuous improvement thrives when engineers are continuously learning.

What this looks like:

Regular “lunch & learn” sessions run by team members

Internal tech talks and demo days

Book clubs or article discussions

Sponsorship for online courses and conferences

Encouragement to explore open source, side projects, or new tools

Also critical: make learning safe. It’s okay to say “I don’t know.” Growth comes from asking questions, making mistakes, and trying again.

8. Celebrate Small Wins and Micro-Improvements

Not all improvement is earth-shattering. Sometimes it’s:

Removing one manual deployment step

Renaming a confusing variable

Adding a helpful README

Refactoring a shared utility

Automating a recurring test failure

Recognize and celebrate these. Improvement is a daily habit, not a quarterly initiative.

9. Tackle Technical Debt Strategically

Tech debt is inevitable. The key is to make it visible, intentional, and manageable.

Do this by:

Tracking it in the same backlog as features

Classifying it (e.g., productivity-affecting, risk-generating, customer-impacting)

Prioritizing and budgeting time for it regularly

Treating debt reduction as a product investment — not a chore

And most importantly, don’t shame past decisions. Debt reflects how your system has evolved — learn from it.

10. Encourage Reflection and Self-Improvement

Beyond team-level change, continuous improvement is also personal.

Help engineers reflect on:

What did I learn this sprint?

What’s one thing I want to get better at this quarter?

How can I improve my collaboration or mentoring?

Managers can use 1:1s to support reflection, identify growth areas, and encourage experimentation with new habits or tools.

Self-aware engineers fuel self-improving teams.

Building a culture of continuous improvement is not a one-time initiative. It’s a cultural muscle that strengthens over time — through leadership, systems, mindset, and consistent reinforcement.

The best engineering teams aren’t just fast. They’re always learning, always adapting, and always raising the bar — together.

So if you’re an engineering leader or team member, ask yourself today:

What’s one small thing we could improve right now? And what would happen if we did that — every week?

That’s how continuous improvement starts.

Maximize image

Edit image

Delete image